Semiconductor Ultra High Purity Gas Solutions

Fixed Gas Purity MonitoringSystems (GPMS)

Gas Purity Monitoring System (GPMS) is a fixed analytical system capable of analyzing trace oxygen and moisture in high purity hydrogen, nitrogen, helium, and argon bulk gases and traces moisture in oxygen and carbon dioxide. The system utilize a series of cavity ring down spectormeters. Each spectrometer communicates with an on-board PLC for outbound communcation with the customers FMS.

We offer a four differernt options, depeding on the combination of gases you need tested.

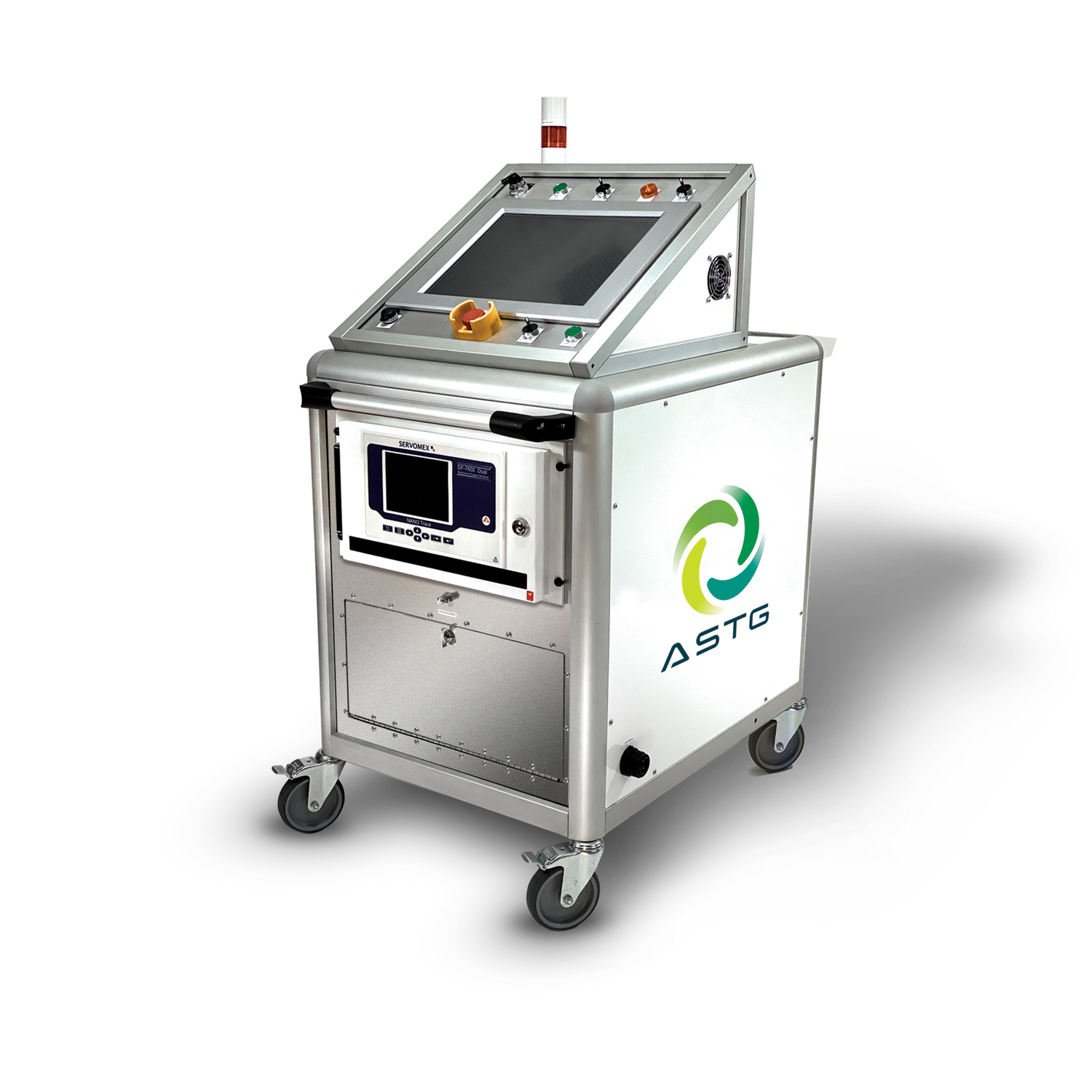

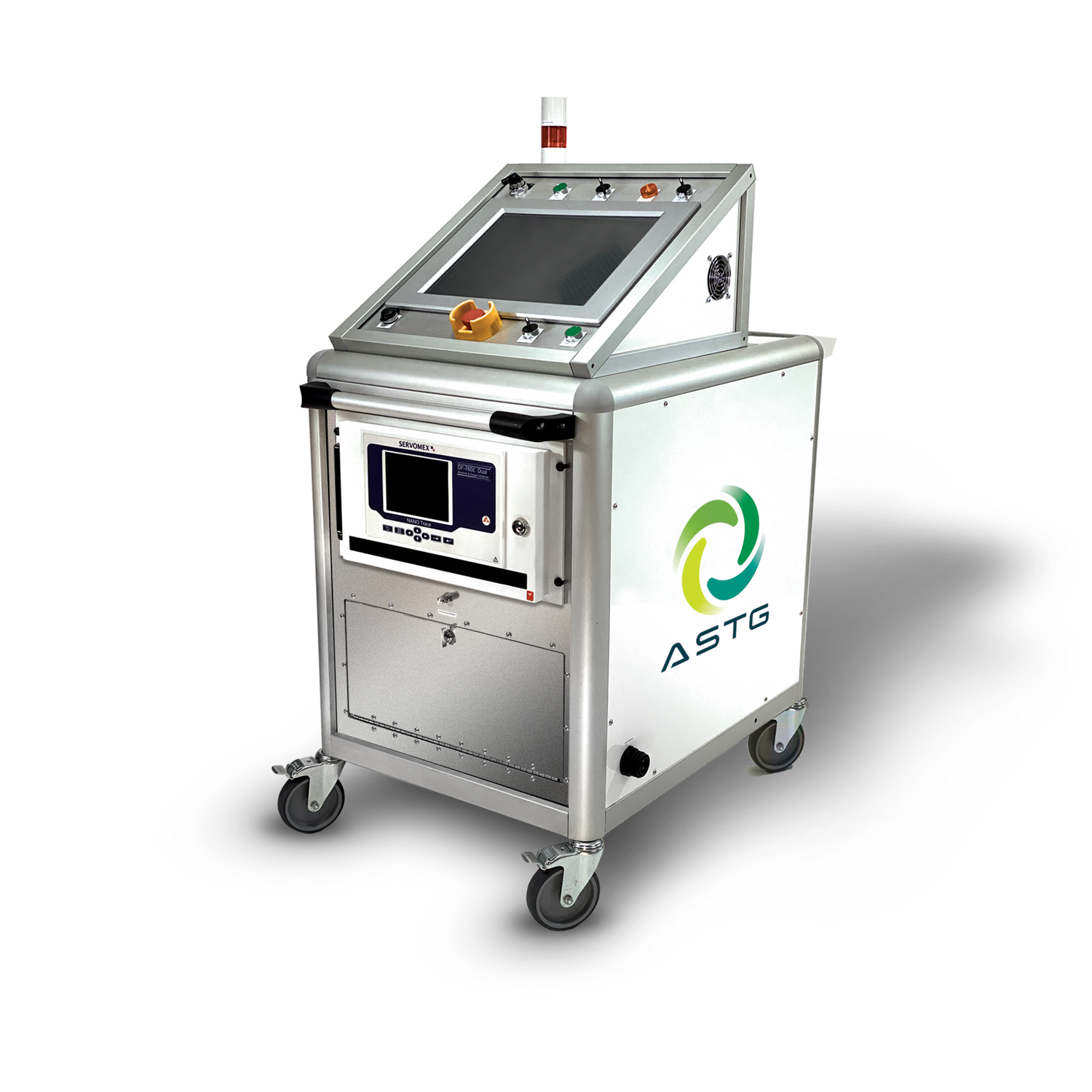

Mobile Gas Analytical Systems(Analytical Carts)

Our carts are mobile, self-contained systems used for the continuous measurement of trace O2 and H2O gas impurities to the part-per-billion level in UHP gases.

Continuous Quality Control CQC GasMonitoring Systems

A continuous quality control gas monitoring system is a real-time, automated setup used to monitor and ensure the quality of gases in various industrial and environmental applications. It consists of sensors and instruments that continuously analyze and report the composition, purity, and various parameters of gases within a specific process or environment. This system provides ongoing data and alerts, allowing operators to maintain consistent gas quality, identify deviations, and take immediate corrective actions if necessary.

Air Separation Unit ASU

An air separation unit (ASU) is an industrial facility designed to separate and produce high-purity gases, such as oxygen, nitrogen, and argon, from atmospheric air. It operates through a process called cryogenic distillation, which relies on the differences in boiling points of various gases. In an ASU, ambient air is compressed and cooled, leading to the liquefaction of air components. These liquefied gases are then separated and purified by distillation at extremely low temperatures.

Final Product Purity Control

STG, a leader in gas purity analysis, presents its flagship product, the Ultra/Gas Analytical Purity Systems. Designed for industries where gas purity is paramount, this system sets new benchmarks for final product purity testing. The system boasts a state-of-the-art design that integrates the latest technological advancements. The Ultra/Gas Analytical Purity System is engineered for optimal performance, ensuring precise measurements even at the most demanding purity levels. Its compact and ergonomic design allows for easy integration into any workspace, while its user-friendly interface guarantees hassle-free operation. Quality is at the heart of ASTG's ethos. Each component of the Ultra-High Gas Analytical Purity System is crafted from premium materials, ensuring durability and reliability. Rigorous quality checks and testing procedures are in place to guarantee that every system meets and exceeds industry standards.

ASTG's system is an investment in efficiency and longevity. Its energy-efficient design and low maintenance requirements reduce operational costs significantly. Additionally, the system's durability means fewer replacements and repairs, ensuring a lower total cost of ownership over its lifespan.

In summary, ASTG's Ultra/Gas Analytical Purity Systems are the epitome of excellence in gas purity analysis. With unmatched design, superior quality, cost-effective ownership, and exceptional customer support, ASTG is setting new standards in the industry, making it the go-to choice for organizations seeking the best in gas purity analysis.

Trailer Fill Solutions

In the dynamic world of gas manufacturing, ASTG stands at the forefront, offering cutting-edge gas analytical technology designed to redefine efficiency and precision. Our Automatic Filling System is a game-changer for gas manufacturers seeking to elevate their operations.

Key Features:

1. Innovative Automation: Our system seamlessly automates the filling of cylinders and trailers, transitioning from manual to a state-of-the-art automated process. This leap in technology not only streamlines operations but also significantly reduces the margin for error, ensuring consistency and reliability in every fill.

2. Speed and Efficiency: Time is of the essence in the gas manufacturing industry. Our system is engineered for speed, significantly outperforming traditional methods. This increase in pace does not compromise quality, ensuring that each operation is executed with the highest level of precision.

3. Transparent Analysis: Transparency is critical in the gas industry. The ASTG system comes equipped with advanced analytical capabilities, providing real-time, transparent analysis of the filling process. This feature guarantees that every step is monitored, recorded, and available for review, offering unparalleled insight into your operations. As part of the ASTG Overwatch system, this data can be made available in real time to manufacturers and customers.

4. Verifiable Provenance: Trust and verification are key. Our system offers verifiable provenance, ensuring that every product's journey from production to delivery is documented and traceable. This adds a layer of credibility and trustworthiness to your products, a valuable asset in today's market.

5. Cost-Effective Operations: Efficiency is not just about speed; it's also about cost. The ASTG Automatic Filling System is designed to be economically advantageous. By streamlining operations and reducing manual labor, it delivers tangible savings to users, enhancing your competitive edge.

6. Customizable Solutions: We understand that each gas manufacturer has unique needs. Our system is designed to be versatile and customizable, capable of adapting to a variety of operational

scales and requirements. This flexibility ensures that the ASTG system is a perfect fit for your business, regardless of its size or scope.

Choosing the ASTG Automatic Filling System means opting for reliability, efficiency, and technological excellence. It's an investment in the future of your operations, aligning your business with the forefront of gas analytical technology. Transform your gas manufacturing process today with ASTG – where innovation meets precision.

AirBreather UHP CO2 Analytical

The ASTG AirBreather UHP CO2 Analytical System is a cutting-edge solution designed specifically to exceed the stringent quality reporting needs of the ultra-high purity carbon dioxide industry. With its advanced technology and precision engineering, the AirBreather system sets a new standard in gas analysis. This system offers unmatched precision and accuracy. The AirBreather system utilizes state-of-the-art sensors and calibration techniques, ensuring unparalleled accuracy in CO2 purity measurements. This precision is crucial for industries where even minute impurities can significantly impact product quality. The AirBreather-UHP is the first system capable of delivering ASML, EUv, Deep UV analytical information at the sub-fab level. Equipped with fast response times, the system offers real-time monitoring and analysis of CO2 purity levels. This feature allows for immediate adjustments in the production process, ensuring consistent quality control and yield maximization.

The system boasts an intuitive, user-friendly interface, making it easy to operate and interpret data. This accessibility reduces the need for specialized training, saving time and resources for the user.

With advanced data logging and management capabilities, the AirBreather System efficiently records and stores purity data. This information is crucial for quality assurance and regulatory compliance. The AirBreather UHP CO2 System is designed to withstand the demanding conditions of ultra-high purity environments, the system is both durable and reliable. Its robust construction guarantees a long operational lifespan with minimal maintenance requirements. Recognizing that different industries have unique needs, the AirBreather System is highly customizable. This adaptability ensures that it can meet specific purity monitoring requirements across various applications. ASTG offers comprehensive support and maintenance services, ensuring that the Airbreather system consistently operates at peak performance.

In summary, the ASTG AirBreather UHP CO2 Analytical System is an exemplary solution for the ultra-high purity carbon dioxide industry. Its advanced features and reliable performance make it an indispensable tool for achieving and maintaining the highest standards of quality and purity.

AirBreather CO2 Analytical Systems

AirBreather Analytical Systems employs new and unique technologies for quality control, quality assurance, and safety. Complete systems reduce cost of ownership and increase throughput while maintaining a performance envelope superior to any other technology.

Cryogenic Purifiers

A cryogenic purifier is a device or system designed to separate and purify gases through the use of extremely low temperatures. It utilizes the principles of cryogenics, which involve the cooling of gases to very cold temperatures, often near or below their boiling points. By cooling gases to such low temperatures, impurities and unwanted components can be condensed and separated from the desired gases, allowing for the production of high-purity gases for various industrial and scientific applications.

Field Regulator Boxes

A field regulator box serves as a crucial component for managing and controlling gas parameters in the field, ensuring the optimal performance and reliability of semiconductor equipment. This specialized box houses regulatory circuits and controls that precisely adjust the gas flow to meet the stringent requirements of semiconductor manufacturing processes.

Fixed Gas Detection

ASTG offers an extensive line of fixed gas analytical systems. These systems can be used for spot-checking manufacturing issues to “battery-limit” testing entire facilities. Our systems are designed using Ultra-High Purity Engineering Techniques.

Gas Blenders

Explore precision gas mixing with our state-of-the-art UHP Gas Blender System, engineered for a wide range of applications in industries such as semiconductor, laboratory research, food packaging, and more. This versatile and dependable system allows for accurate blending of gases to meet your specific requirements, ensuring consistent and controlled gas compositions.

ASTG-RBS System- The Remote Blending System marries the best feature of a computer-controlled mass flow blending system with the convenience of remote I/O blend modules. The system is divided into two functioning elements- the Control Head and the Dilution I/O®.

Gas Sample Distribution Manifold

The flag ship gas management system, ASTG can automate your UHP gas analytical systems in the smallest footprint possible in orbitally welded components. Utilizing gas-actuated stainless steel diaphragm valves, manifolds can asynchronously port multiple samples, calibration gases and zero gases throughout your analytical system without fear of cross contamination or leakage. High speed activation legs are included on all systems to insure the fastest, most representative sample possible. This will ensure process and quality control when it’s most critical.

Gas Sample Stream Switching System

Unleash precision and control in your gas management processes with our cutting-edge Gas Stream Selector System. Engineered for efficiency and safety, this system empowers industries with the ability to manage, switch, and control gas streams seamlessly. Whether you're in the realm of industrial manufacturing, research and development, or laboratory operations, our Gas Stream Selector System is your trusted partner for enhanced gas management.

Laser & Toxic Gas Cabinets

Depending on the blend tolerance requirements ASTG offers a range of options to meet the needs of the application. From systems designed with fixed orifices to actively managed mass flow controllers and the addition of active analysis on the product stream to adjust the blend mass flow controllers continuously to maintain the blend ratio as the instantaneous flow demand varies, ASTG has the level of expertise required.

Low Pressure Sampling Kits

Engineered as portable, non-hazardous solutions for sampling, our low-pressure gas sampling kits are designed to take safe, repeatable samples from any high-pressure liquid or gaseous cryogenic source.

ASTG offers multiple types of low-pressure gas sampling kits.

LPMS-CRYO- Suitable for any liquid cryogenic sample

LPMS-MIOGI-Q- specifically designed to sample cryogenic oxygen purity to 99.9%

LPMS-CO2 - Suitable for sampling any liqud or gaseous carbon dioxide source

LPMS-ABO- Deisgend specifically for sampling Aviator Breathing Oxygen

PCAS-200

The PCAS-200 cart is a mobile, self-contained system for the continuous measurement of trace H2O gas impurities to the part-per-billion level in UHP gases.

PCAS-500

The PCAS-200 cart is a mobile, self-contained systems used for the continuous measurement of trace O2 and H2O gas impurities to the part-per-billion level in UHP gases.

Thermal Converters

This unit is designed to use clean, dry air as an oxidizing gas. The amount and proportion of the gas may be adjusted to maximize converter efficiency. Air should be run at a state of excess relative to the total sulfur content to prevent a limited reaction.